DROP TOWER DT-202AIR

Drop Tester for Mobile Products of complex-shaped design

The Ideal Model for Drop Testing of Complex-Shaped Products

The lightweight drop tester DT-202AIR inherits the highly repeatable drop performance established by the DT-202 over many years. By adopting a vacuum suction system to hold test samples, it enables reliable drop testing of products with complex shapes and flexible containers—such as wireless earphones, game controllers, smartwatches, and pouch-type packaging.

Movie

Feature

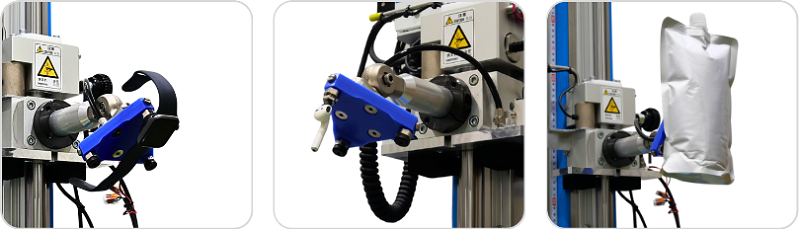

- Equipped with a structure that securely holds test samples by vacuum suction, making it highly suitable for drop testing of products with complex geometries or flexible containers.

- A variety of suction pads are available to accommodate different sample sizes and weights.

- The suction angle can be freely adjusted, enabling highly repeatable drop tests on corners and edges.

- Drop operation can be switched to a remote controller (optional) for enhanced usability.

Versatile Vacuum Suction System

Optimized for drop testing of various product shapes, including wireless earphones, game controllers, smartwatches, and pouch containers.

By adjusting the holding angle of the fixture, drop tests can be performed in any desired orientation.

Simple Operation

- Test samples can be securely fixed at any desired angle using the suction pad, with a single button.

- Drop testing is initiated simply by pressing the switch on the controller (remote control).

- Drop height can be freely and quickly adjusted using the scale.

Specification

| Model | DT-202AIR | ||

|---|---|---|---|

| Test sample maximum weight (kg) | 1.5 | ||

| Drop height range (mm) | 250 ~ 2000 | ||

| Drop height setting method | By the scale and setting guide | ||

| Drop motion of test sample support table | By the permanent electromagnetic holder | ||

| Fastening and releasing operation of test sample | By the vacuum suction | ||

| Dimension of tester (mm) | W600 × D500 × H2382 | ||

| Mass of tester (kg) | about 80 | ||

| Base thickness (mm) | 16 | ||

| Feed air pressure | higher than 0.35MPa,23dm³ over | ||

| Power supply | AC100 ~ 240V, single phase, 5A | ||

| Operation environment temperature (℃) | 5 ~ 35 | ||

| Option | Casters, Remote controller, Additional stand for shock absorber, Air compressor | ||

High Speed Camera System - optional

We also offer systems that combine high-speed cameras with the drop tester. By visualizing product behavior and damage conditions under drop shock, this solution contributes to more efficient product design. For further details, please feel free to contact us.