Shock Test

Shock test gives the mechanical acceleration pulse toward the product and confirms the shock quality of test peace.

Generally, this test is needed for product itself, its device inside and material on it. Sometimes, this test can be a part of contract for product selling in the market.

Recently, the needs of high acceleration pulse intend to increases. A background of this, some study shows mobile products encounter the high shock acceleration by free fall at 1m.

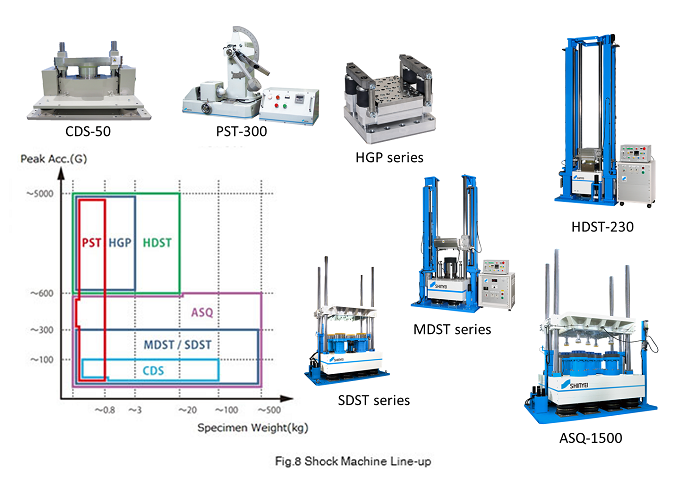

Shock test has been practiced from large product to small one. The appropriate testing machine should be selected based on weight and size of product or testing standards.

Shock Machine

Shock machine (ASQ, MDST, SDST series) has a shock table which sets the product on, and can confirm product damage by generating requested shock pulse above the table. Generated shock pulse should be selected by testing standard. Shock pulses are controlled by drop height and elastic characteristics of cushioning programmer. Shock table size can be selected from 150x150 to 1500 x 1500 mm depends on your products.

Shock Machine with High Acceleration

High acceleration pulse machine can generate maximum 50000m/s^2(5000G) and table size is 230x230mm.

Shock test for mobile products and parts of it applies to the compact pendulum shock machine, PST300. This machine has rotatable shock table and can generate the shock pulse on the table by rotational drop the any angle position you can set.

Shock pulse is measured by acceleration measuring system called Shock Manager, SM-500, whose available channels are max. 10ch. We can confirm the criteria of shock pulse or control of shock machine. Also we can find the output shock pulse on the product when acceleration pick up installed on the product not only on the shock table.