Necessity of Drop & Shock Testing

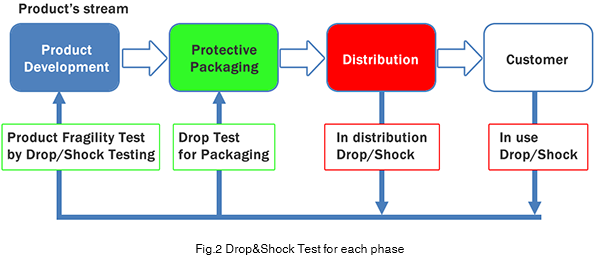

In the process of development new products to actual use, drop/shock event which need to pay attention are 2 points in Fig.2. One is the distribution process and another one is usage of the product. That point is considered by characteristics of each product, and which hazard should be thought more importance. For example, installing products, (TV or refrigerator, etc.) should be cared the distribution hazard because they will not encounter at higher drop in usage environment. On the other hand, smart device, small products, should be considered its usage environment because these devises will encounter the higher drop than distribution.

Shock test which simulated these hazards has carried out to measure product’s shock durability. These tests need testing machine with easy use, safety and high repeatability.

Sometimes, drop test has been carried out by handwork because of its easy operation. However, result from human operation isn’t steady since it depends on the personal skill and do not have repeatability with accuracy. Also it is difficult to conduct the drop test with high safety for heavy product. In this case, we can’t find the best feedback to product development and danger for a person who carried out the drop test. So we need a drop tester with safety and accuracy repeatability with easy use, Fig.3.

Mechanical shock machine has been provided to apply 2 types of tests – one is high velocity change to the large and heavy product, another one is high peak acceleration to the small products itself or it’s inside device with.

In the case of shock testing system, anyone can carry out the shock test with easy operation to measure acceleration pulse on the shock table.

-

Fig.3 Drop Tester for Mobile Products

-

Fig.4 Shock Machine